Digital Twin of Data, AI: Inside MITS Mumbai 2024

Param

2 mins

As India's economic engine roars, the demand for sustainable and efficient manufacturing solutions grows louder. The Manufacturing IT Summit 2024 India addressed this critical need, fostering discussions on integrating renewable energy with cutting-edge smart technologies to create a future-proof manufacturing landscape.

At the forefront of the recently concluded event in Sahara Star, Mumbai, leaders from the manufacturing industry gathered to share insights and discuss the latest technology trends, challenges, and innovations. Industry experts from sectors including automotive, renewable energy, pharmaceuticals, food and beverage, and heavy industry engaged in in-depth discussions on digitization, security enhancements, and the deployment of advanced networks in new and existing plants.

Keynote: Manufacturing 2030 - Pioneering India’s Industrial Renaissance

The summit began with a keynote session. The opening keynote took attendees on a visionary journey, outlining a roadmap for India's manufacturing landscape over the next decade. This session highlighted how smart factories, sustainable practices, and global competitiveness will position India as a leader in the next era of intelligent manufacturing.

Key Panel Discussions at Manufacturing IT Summit

Visionary insights outlined a roadmap for India's manufacturing future, highlighting smart factories, sustainability, and global competitiveness. Over 25 sessions and 500 delegates exchanged knowledge on achieving a greener future. Some noteworthy panel discussions included:

Revolutionizing the Factory Floor: A Symphony of Data, Cloud, and AI

This panel explored how real-time data collection and analysis, predictive maintenance, and connected devices enhance efficiency, product quality, and safety. Key topics included using data analytics and machine learning to process large data sets, securing IoT devices and networks, and employing digital twins to reduce downtime. The role of robots and drones in creating connected enterprises and the importance of human-machine collaboration were also discussed.

In Sync and Secure: Cybersecurity Strategies for IT/OT Harmony

Discussions focused on the convergence of IT and OT and the associated cybersecurity challenges. The panel emphasized Zero Trust principles, robust IAM practices, and the need for seamless collaboration between IT and OT teams. Network segmentation was highlighted as a crucial strategy for containing cyber threats and minimizing lateral movement.

Connected, Adaptive, Autonomous: The Dawn of Industry 5.0 in Manufacturing

This session highlighted how IoT sensors and predictive analytics minimize downtime through proactive maintenance. The role of blockchain in ensuring trust and transparency in supply chains, the use of digital replicas for enhanced monitoring and maintenance, and the impact of high-speed connectivity and edge computing on real-time decision-making were key topics.

Electrifying the Road Ahead: India’s Automotive Revolution

The panel discussed the swift adoption of digital twins and the replacement of quality inspectors with sensors and cameras. The transition to Lean-Intelligent-Manufacturing (LIM), the shift to electric vehicles (EVs), and IT-driven strategies for enhancing customer experience were explored. The integration of AI in autonomous vehicles and the unique cybersecurity challenges of IT systems in the automotive industry were also covered.

Green Horizons: Navigating Sustainable Practices in Manufacturing

Sustainability was a recurring theme throughout the event. Sessions dedicated to renewable energy integration showcased how solar, wind, and other renewable sources can be incorporated into manufacturing processes. They demonstrated successful implementations where manufacturers have reduced their carbon footprints and operational costs by adopting sustainable energy solutions.

This discussion emphasized the importance of sustainable practices in manufacturing, exploring government policies and successful case studies. The need for collaboration between government, manufacturers, and other stakeholders was highlighted, along with potential solutions and best practices for sustainable development.

Sedin’s Exclusive Session: Data & AI- Twin Engines Driving the Manufacturing Digital Ecosystem

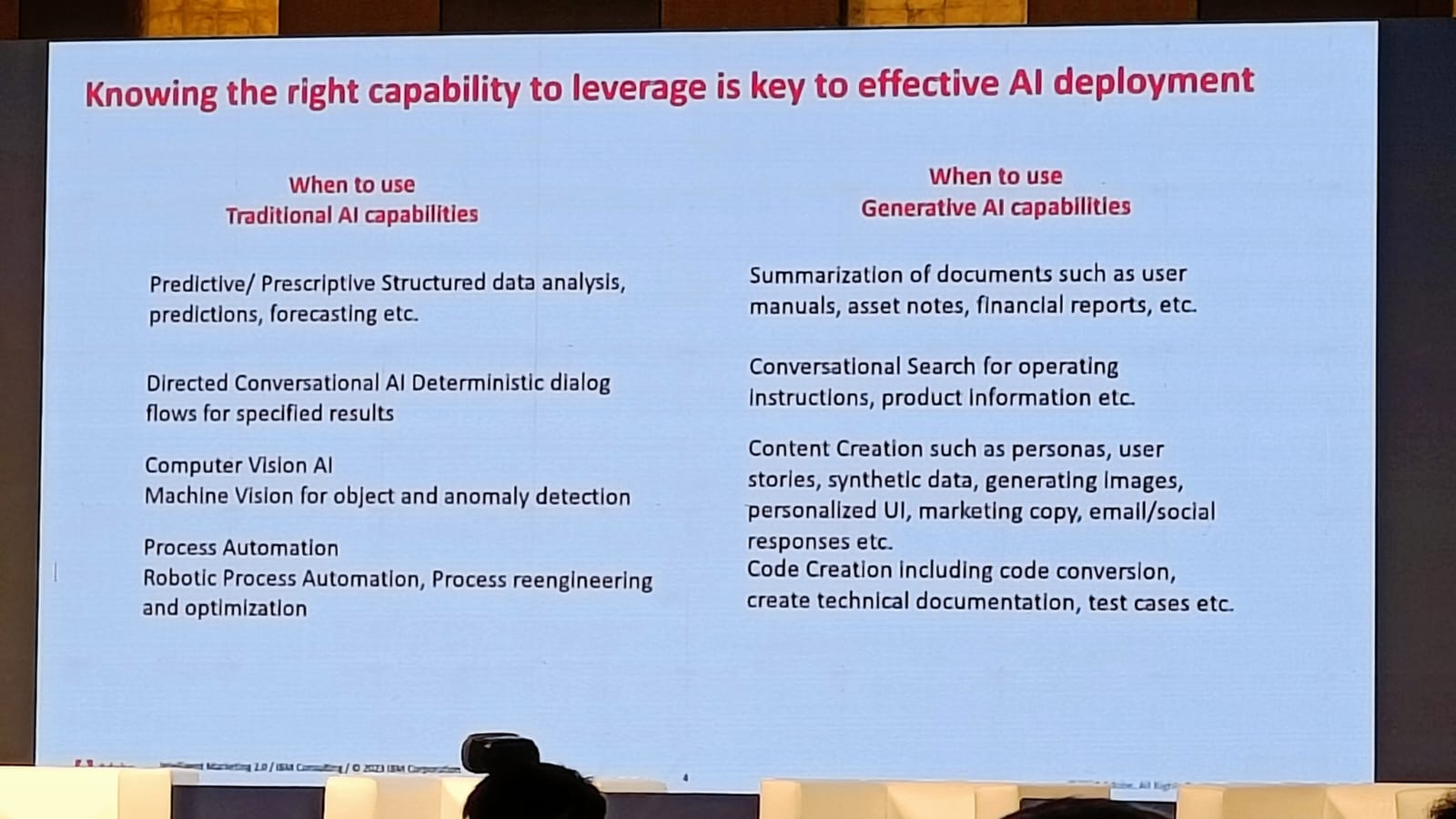

Sedin played a significant role at MITS Mumbai 2024 with an engaging speaker session focused on the transformative power of data and AI in revolutionizing the manufacturing industry. Our experts emphasized the concept of the digital twin, a revolutionary technology enabling manufacturers to create virtual replicas of physical assets, processes, and systems. These digital counterparts empower real-time simulation, prediction, and optimization, leading to substantial improvements in efficiency, productivity, and cost savings.

Data and AI were pivotal themes at the summit, underscoring their critical role in the era of Industry 4.0. The ability to collect, analyze, and leverage data is now indispensable for manufacturers striving to maintain competitiveness. AI-driven analytics provide unprecedented insights, enhancing decision-making processes and fostering continuous innovation across manufacturing operations.

Conclusion

The future of manufacturing is undoubtedly digital. Real-time data, sophisticated analytics, and innovative strategies continue to shape the industrial and smart manufacturing landscape. The integration of digital twins, data, and AI is not just a trend but a fundamental shift towards a more connected, intelligent, and efficient manufacturing ecosystem. Companies that embrace these technologies will be better positioned to navigate the complexities of the modern industrial landscape, drive growth, and maintain a competitive edge.

Join us on our journey as we explore these fascinating topics and more, shedding light on how emerging technologies are transforming every facet of our lives. See you next year for more exciting manufacturing innovation!

Stay up-to-date with the latest insights and news from Sedin

Subscribe to email updates